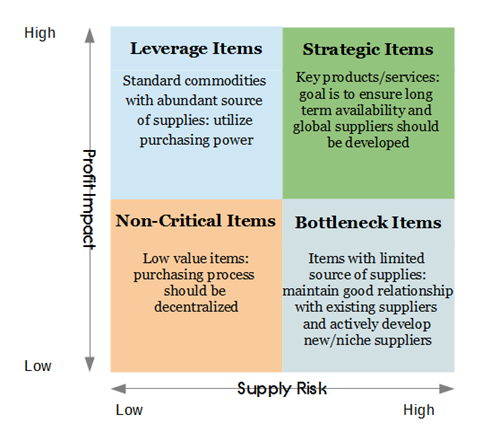

More than thirty-five years ago purchasing analyst Peter Kraljic created what is called the Kraljic Matrix, a portfolio purchasing model for companies based on a two by two matrix of risk versus profitability: (Harvard Business Review, September 1983)

*Leverage items= High Profit/Low Supply Risk

*Leverage items= High Profit/Low Supply Risk

*Non-Critical Items=Low Profit/Low Supply Risk

*Strategic items=High Profit/High Supply Risk

*Bottleneck items=Low Profit/High Supply Risk

Kraljic defined risk as the probability for an unforeseen event to disrupt supply chain viability; profitability as the impact of a supply item upon the bottom line. Moreover, he observed that purchasing practices historically had been largely a function based on routine, a practice that was outdated even by 1983 standards; a remnant of a time when the marketplace was relatively stable. Rethinking the wisdom of such complacency requires a total change of perspective from purchasing as merely an operational function to one of supply management: applied strategy in the purchasing arena. (Forbes Magazine, February 2017)

We’ll address here only the quadrant of the risk/profitability matrix that covers leveraged items. Buyers functioning in this quadrant of the matrix are in a position of power and can leverage it to achieve greater returns on every dollar spent, but just as importantly, ensure that the business has the materials needed to run the business. In this way, suppliers are somewhat interchangeable as purchasing power is directed toward parts that are largely commodified but necessary for day-by-day operations.

Nowhere is this more apparent than in MRO spend. (Maintenance, Repair and Operations) Stringent monitoring is required to ensure that balance is achieved with enough materials on hand to service both the internal and external customer. But not so much as to accumulate inventory in danger of obsolescence or result in excess supplies taking up valuable warehouse space.

For example, a manufacturer isn’t going to be happy when a new customer’s order isn’t going to be delivered as promised because it has just been realized that a part needed in manufacturing is not where it’s supposed to be, even though the material masters indicate that there are adequate parts on hand. Disappointed also is the man on the production line who is taking heat from his foreman about generating product for which he is lacking the raw material. He may or may not understand that the material masters is the culprit for obscuring the real state of available parts inventory; he only cares about the fact that he is being held responsible for holding up production with a tight deadline looming.

Data related to MRO spend must be examined critically because poor data quality is often the result of duplicate, inconsistent and inaccurate material masters. Buyers and other stakeholders trying to get a grip on their company’s available inventory can be left with a jumbled tangle of data inconsistencies to sort through as they try to make sense of it all.

Benefits of Reliable Material Masters:

- Inventory management is optimized.

- Planned maintenance can be set up to automatically trigger purchase orders based on the material masters.

- Inventory carrying costs are reduced.

- Duplicate purchases are reduced because materials are visible and easily tracked.

- The amount of time required by buyers to review and process free text items is decreased.

- Spend is leveraged, embodying process efficiency and lean management.

- Executive decisions can be based on accurate and complete data.

- The buyers time is maximized by utilizing most repeated purchases on high volume, repetitive purchases.

- Off-contract spend can be significantly lessened.

- Increased accountability is provided for budgeting and purchasing, allowing departments detailed spend.

- Forecasting/planning capabilities are improved.

A Perfect World for MRO Spend:

According to procurement and intelligence company Beroe, Inc., leveraging MRO spend is beyond conventional wisdom, embodying emerging best practices and developments in MRO procurement and ventures. In addition to traditional methods of criticality analysis, demand analysis, MoQs (Minimum Order Quantities) and volume aggregation, new practices demand absolute data integrity and precision of order information. Manufacturer Parts Numbers and the OEM (Original Equipment Manufacturer) can be critical for evaluating a supplier’s prices. Along with UoM, (Unit of Measure) to assure data standardization, all are needed to apply an apples-to-apples comparison when going to market.

Discounts are another avenue for leveraging spend. Providing estimated annual volumes can be critical, especially for suppliers who are willing to reduce their own margins in favor of increasing their overall sales. And as in the case of cost-plus scenarios, helps procurers get discounts on direct margins instead of the discounts on catalog or web prices which tend to be largely inflated—obscuring the size of the discount actually being offered. There are also annual rebates and tiered discount structures to consider. Procurement professionals need to be aware that prevalent margins and discount ranges are made available by suppliers at different spend levels.

Suppliers wanting to retain business should also be able to recommend alternative brands or cross items that could further reduce cost and help in maintaining a manufacturer’s viability and increase durability of MRO spares.

But to the heart of the matter: Leveraging MRO spend depends upon accurate and reliable material masters.

The Answer:

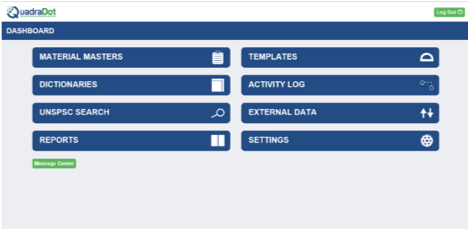

Granite software from QuadraDot can help your company get a well-defined picture of buying routines by initiating best practices  data management. After all, data used to make purchasing decisions is only as valid as the material masters from which it is drawn.

data management. After all, data used to make purchasing decisions is only as valid as the material masters from which it is drawn.

For instance, an in-depth analysis of one business seeking answers to the inconsistent data found on their material masters learned that thousands of master records were found to contain substantial quality issues. Multiple thousands more were comprised of free text materials on purchase orders. Free text meaning that the naming taxonomy used to initiate the order was left to the discretion—or perhaps creativity—of the person initiating the order, with perhaps confusing results.

Inaccurate data makes everything more complicated when a company is trying to accurately assess past buying behavior as well as justify future purchasing decisions. Our user-friendly proprietary software, Granite Material Masters™, will create a proper data taxonomy, working as a team with a company’s in-house stakeholders to configure the software with any existing ERP or Warehouse Management Software already in place.

So, the next time that the production line gets called upon to expedite an order for a new customer, the man responsible for filling the order has what he needs to complete the order. He’s happy, his foreman is pleased, and the manufacturer is ecstatic. But, perhaps the most delighted of all is the new customer who got exactly what he wanted when he wanted it.

The Kraljic matrix is as relevant now as it was nearly forty years ago. But, leveraging MRO spend takes strategic planning because today’s complex buying marketplace is beyond the matrix. To optimize their purchasing power, procurement agents need to make complicated decisions in a buyer’s market. But to operate effectively, the first requirement is to create materials masters that are held to higher standards of data integrity—standards delivered by the Granite Material Masters™ software and QuadraDot consulting services. Navigating beyond the matrix just became simplified…the QuadraDot way.